Charcoal making is an age-old practice that has been passed down through generations. It is an art that harnesses the natural energy of wood to create a powerful and versatile material. From cooking and heating to purifying air and water, charcoal has been used for countless purposes throughout history.

Charcoal making is a fairly easy process, and requires a little equipment and some time. The process of transforming wood into charcoal involves carefully controlled heating, which removes moisture and impurities, leaving behind a carbon-rich substance with a myriad of applications. So, let’s explore the fascinating world of charcoal making and discover the diverse benefits this remarkable substance offers!

Charcoal has lots of uses, from purifying water to providing fuel for cooking. If you enjoy a BBQ or cooking outdoors, then making your own charcoal can save you money. Plus, it is a good way to use up any scraps or off-cuts of wood you might have about the place. You could even make charcoal to sell at farmers’ or foodies’ markets, or rural events.

What is the Best Wood for Making Charcoal?

To make charcoal for cooking, you must have the right sort of wood. Untreated hardwood timbers scraps or off-cuts are fine, as is wood from hardwood trees. Hardwood simply means wood from a tree that is deciduous, that loses its leaves in winter and buds again in spring. Oak, Hazel, Chestnut, Maple, Apple are all examples of hardwood trees that make good charcoal for cooking.

Wood for charcoal making should be well seasoned, not freshly cut green wood. Seasoned wood is wood that has been stacked somewhere dry and airy for approximately six to eight months, allowing the moisture content to slowly evaporate. If you burn green wood, all you get is a load of damp smoke.

Two Ways of Making Charcoal

To make charcoal, wood needs to burn slowly with no air around it, otherwise it will just turn to ash. Some sort of container is required to create the right environment. If you want to make charcoal on a larger scale, for example to make a profit from woodland, there are charcoal kilns specially designed for the job. However, for smaller scale charcoal making, a steel oil drum works well, provided it is clean. One end of the drum is cut off to be used as a loose fitting metal lid, with a few holes in the top.

There are two main methods of making charcoal – direct and indirect.

The Direct Method

This is perhaps the easiest way to make charcoal. The direct method is to make a fire in a container, then add wood to it. Once it is burning, you cover the container loosely with a metal sheet to restrict the air. Watch as white smoke and steam from the wood comes out of the gaps around the cover.

When it turns to a blue coloured smoke, any moisture from the wood has dried. You then completely stop any oxygen from entering the container by closing off the holes or gaps. Sand or soil work well. Without air, there is no flame, so the wood inside smoulders and cools. Leave it for 24 hours before removing the lid, to ensure everything has cooled down. The container should have charcoal ready for use.

The Indirect Method

The indirect method of making charcoal is to fill a steel container with wood, then build a fire around it. Because of the amount of wood you need to burn to get charcoal using this method, it is more suited to making small amounts, perhaps for purposes other than cooking fuel. The benefit of the indirect method of charcoal making is that it allows you to produce small amounts fairly quickly.

Build a fire in a safe area, or use a fire pit. Find a suitable metal container with a removable loose lid. Make a hole in the lid. It is important that the lid is loose, so that pressure doesn’t build up in the container as it heats, causing it to explode and possibly injure someone.

Wrap some metal wire around it so you change the position of the container once it is on the fire, and can hook it out again when it’s hot. Fill the container with wood and put on the lid. Use long handled tongs or a stick to put the container into the fire.

White smoke will come out of the hole in the top of the lid, which will become flammable. Keep an eye on the container. When the smoke and gasses from the lid are no longer flammable, carefully remove the container from the fire. Leave the lid on an allow it to cool completely before opening.

Charcoal Making – The Results

When you remove the lid from the drum, you should see blackened chunks of coals. There should not be any wood or ash visible. Charcoal making is an art, as well as a science, so getting it right might take a little practise.

Using homemade charcoal is a sustainable way of producing fuel for the home. Using coppiced timbers from hardwood trees is healthy for woodland management, and any smoke created during the process is nothing compared to the carbon footprint of imported charcoal.

Charcoal ash that is left over from cooking, or from being used in a wood-burning stove, is a good fertiliser for growing plants. Making charcoal has lots of benefits, so give it a try!

Need more advice on making your own Charcoal?

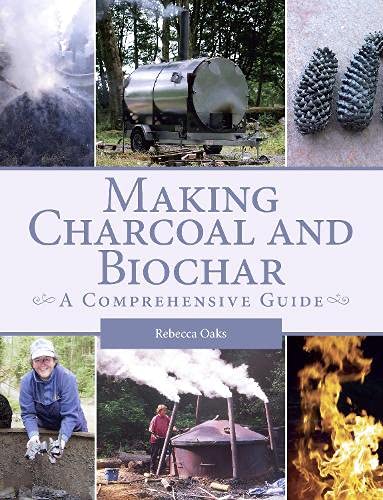

Explore the fascinating world of Making Charcoal and Biochar: A Comprehensive Guide.

This book offers valuable insights into the art of charcoal making. This comprehensive guide aims to inspire and engage readers, ensuring that anyone who gives charcoal making a try will soon fall in love with the process.

Inside, you will find a range of possibilities for making charcoal on a small scale or even for commercial production. Chapters cover various techniques, from the traditional heritage skills of earth burns to the enduring popularity of metal kilns and the innovation of charcoal retorts.

The book also delves into the intriguing topic of biochar, sometimes referred to as “small particle charcoal.” This substance has been hailed as a potentially beneficial tool for increasing soil fertility and productivity while effectively capturing carbon in the ground.

Making Charcoal and Biochar concludes with a celebration of the countless practical applications of charcoal. From cooking and heating to air and water purification, the versatility of this material is truly remarkable. A must for anyone thinking about making their own charcoal! Check the latest price.

Do you make your own charcoal? Please share your tips!

If you you know want to find out more about woodland management topics, pop you name on the mailing list, and I’ll let you know when there are new post that will interest you.

Pingback: What is charcoal made from? – Wonderings in the Woods